How Pre-Construction Treatment Works:

The application process typically involves these steps:

- Soil Treatment: The primary focus is on creating a chemical barrier around the foundation. A termiticide solution is applied to the soil surrounding the foundation trench and beneath the concrete slab. This creates a zone of protection that deters termites from entering the structure.

- Foundation Treatment: The termiticide solution might also be applied directly to the foundation walls themselves. This creates an additional layer of protection and ensures complete coverage.

- Plumbing and Electrical Conduits: These potential entry points for termites are also treated with the termiticide solution to prevent them from becoming pathways for infestation.

Building Materials: In some cases, pre-treated building materials infused with termiticides might be used for specific structural elements like crawl space posts or wooden components near the foundation.

THE WORK OF ANTI-TERMITE TREATEMENT:

Soil Treatment for Anti-Termite as specified in the Scope of Work included The Work is generally described as.

Standard operating procedures (SOPs)

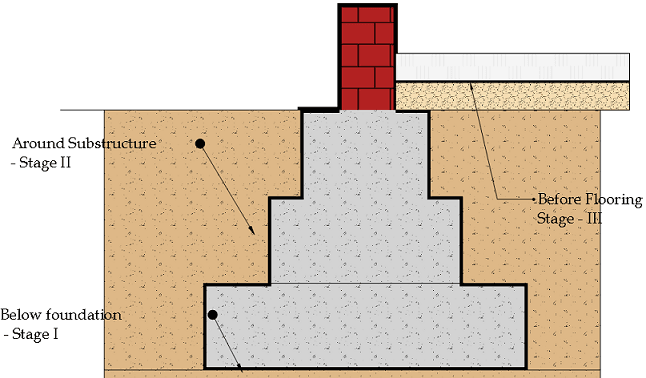

- Foundation stage- spray treatment (When Excavation)

- Foundation stage- spray treatment(When Filling Excavation)

- Foundation stage- spray treatment (When piling is completed)

- Ground beam level- Spray (After pile cap or pedestal erection)

- Plinth level- spraying or chemical filling (Before and After soling & compaction)

Anti-termite Treatment Chemicals

The treatment shall be carried out strictly in accordance with the technical specification and conforming to IS 6313 part II or equivalent BS specification. The chemical to be used as insecticides for the treatment shall be CHLOROPYRIPHOS 20% (or) 50% EC and the application shall be dilute one part of chemical 20% or 50% EC with 19 or 49 parts of water to get 1% emulsion and strictly in accordance with the manufacturer’s specification.

Either one of the below chemicals can be used for the treatment as per the Indian standard.

A certified and experienced agency should execute the Anti-Termite treatment as per the below mentioned IS standards.

| IS CODE | DESCRIPTION |

| IS 6313 Part I | Constructional Measure |

| IS 6313 Part II | Pre-construction Anti Termite measure |

| IS 6313 Part III | Treatment for Existing building |

Materials and Equipment Requirement

- Chloropyriphos 20% EC (Chemical)

- Add 1 part of Chlorpyrifos 20% EC with 19 parts of water (1:19 ratio)

- Measuring cane (20 Liters)

- POST CONSTRUCTION ANTI TERMITE TREATMENT

- PRE CONSTRUCTION ANTI TERMITE TREATMENT

- ANTI TERMITE PIPING SYSTEM

Pre-Constructional Chemical Treatment IS 6313 (Part 2)

Soil Treatment:

Treating the soil beneath the building and around the foundations with a soil insecticide is a preventive measure. The purpose of the treatment is to create a continuous chemical barrier between the ground from where termites come and woodwork or other cellulosic materials in the buildings. The chemical solution shall be applied uniformly at the prescribed rate in all the stages of the treatment. Hand operated pressure pump with sprayer or an electrically operated pump with sprayer shall be used for uniform spraying of the chemical solution from graduated containers. Alternatively watering can with sprayer may also be used depending upon site specific constraints

a) Treatment for Masonry foundations and Basements (Load bearing structures)

b) Treatment for RCC Foundations (Buildings without Basements)

c) Treatment to RCC Basement Buildings.

d) Common treatments for the above a, b and c.

a) Treatment for Masonary foundations and Basements (Load bearing structures)

i) Treatment to Trenches Made for Foundation of Masonary Walls or Basement

Once the trenches for foundation is excavated treatment will start from the bottom surface and sides upto 300 mm of trenches shall be treated with chemical emulsion @5 ltrs/sqmt.

ii) Treatment to Vertical Backfilled Soil Along Masonary Foundation/Retaining Wall

After the masonary foundations come up, the backfill in immediate contact with the foundation structure shall be treated at the rate of 7.5 l/m2 of the vertical surface of the sub-structure for each side. If water is used for ramming the earth fill, the chemical treatment shall be carried out after the ramming operation is done by rodding the earth at 150 mm centres close to parallel to the wall surface and spraying the chemical emulsion at the above dosage. After the treatment, the soil should be tamped in place. The earth is usually returned in layers and the treatment shall be carried out in similar stages. The chemical emulsion shall be directed towards the masonary surfaces so that the earth in contact with these surfaces is well treated with the chemical.

iii) Treatment of Top Surface of Plinth Filling

The top surface of the consolidated earth within plinth walls shall be treated with chemical emulsion at the rate of 5 lit/sqm of the surface before the sand bed or sub-grade is laid. This treatment shall also be carried out on DPC provided on plinth wall. If the filled earth has been well rammed and the surface does not allow the emulsion to seep through, holes up to 50 to 75 mm deep at 150 mm centres both ways maybe made with 12 mm diameter mild steel rod on the surface to facilitate saturation of the soil with the chemical emulsion.

iv) Treatment at Junction of the Wall and the Floor

Special care shall be taken to establish continuity of the vertical chemical barrier on inner wall surface from ground level up to the level of the filled earth surface. To achieve this, a small channel 30 mm x 30 mm shall be made at all the junctions of wall and columns with the floor (before laying the sub-grade) the rod holes made in the channel up to the ground level 150 mm apart and the iron rod, emulsion poured along the wall at the rate of 7.5 l/m2 of vertical wall or column surface so as to soak the soil right to the bottom. The soil should be tamped back into place after the operation

a) Treatment for RCC Foundations (Buildings without Basements)

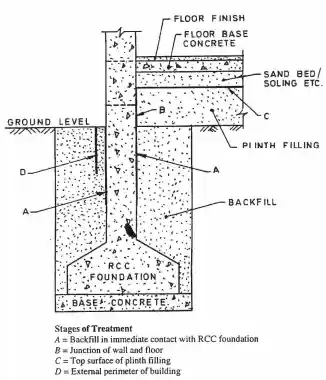

i) In the case of reinforced cement concrete (RCC) foundations, the treatment shall start at a depth of 500 mm below the ground level except when such ground level is raised or lowered by filling

b) Treatment for RCC Foundations (Buildings without Basements)

i) In the case of reinforced cement concrete (RCC) foundations, the treatment shall start at a depth of 500 mm below the ground level except when such ground level is raised or lowered by filling.

Or cutting after the foundations have been cast. In such cases, the depth of 500 mm shall be determined from the new soil level resulting from the filling or cutting mentioned above, and soil in immediate contact with the vertical surfaces of RCC. Foundations shall be treated at the rate of 7.5 ltrs/sqmt.

Treatment of Top Surface of Plinth Filling

The top surface of the consolidated earth within plinth walls shall be treated with chemical at the rate of 5 1/m2 of the surface before the sand bed or subgrade is laid. If the filled earth has been well rammed and the surface does not allow the emulsion to seep through, holes up to 50 mm

centres both ways may be made with 12 mm dimeter mild facilitate saturation of the soil with the chemical.

Treatment at Junction of Wall and Floor

Special care shall be taken to establish continuity of the vertical chemical barrier on inner wall surface from ground level (where it had stopped with the treatment described in 7.3.1) up to level of the filled earth surface. To achieve this, a small channel 30 mm x 30 mm shall be made at all the junction of wall and columns with the floor (before laying the sub-grade) and the rod holes made within the channel up to the ground level 150 mm apart and the iron rod moved backwards and forward to break up the earth and chemical poured along the wall at the rate of 7.5 l/m2 of vertical wall or column surface so as to soak the soil right to the bottom. The soil should be tamped back into place after the operation.

C) Treatment to RCC Basement Buildings

The treatment starts after the excavation for basement is complete and before laying soling and Plain Cement Concrete (PCC). The treatment shall be carried out in the following stages.

i) Treatment to Soil Below Raft

Before laying the rubble soling and PCC, the compacted and levelled soil shall be treated at 5 litrs/sqmt. In case of soils/sand filled above the raft, the treatment at 5 l/m2 shall be carried out on the top surface of filled soil/sand. In such case, treatment to soil/sand below raft may not be necessary

Treatment to Soil Along the Retaining Wall

c). Treatment for Rec Basement Building- Stages of Treatment

The Soil coming in contact with retaining walls shall be treated at the rate of 7.5 l/m2 of the vertical surface so as to effect a continuous outer chemical barrier, in continuation with that of the one formed under the above “i) Treatment to Soil Below Raft”. The treatment shall follow the back filling in stages of 300 mm. However rodding may be carried out to facilitate the treatment.

d) Common treatments for all the above a, b and c.

i. Treatment of soil surrounding pipes, wastes and conduits When pipes, wastes and conduits enter the soil inside the area of the foundations, soil surrounding the point of entry shall be loosened around each such pipe, waste or conduit for a distance of 150 mm and to a depth of 75 mm before treatment is commenced. When they enter the soil external to the foundations, they shall be similarly treated at a distance of over 300 mm unless they stand clear of the walls of the building by about 75 mm

Understanding Termite Threats

Termites are often referred to as “silent destroyers” due to their ability to chew through wood, flooring, and even wallpaper undetected. They thrive in warm, moist environments, making Pune’s climate particularly conducive to their proliferation. The risks associated with termite infestations include:

- Structural damage that can compromise the integrity of buildings.

- High repair costs that can strain budgets significantly.

- Decreased property value due to visible damage and infestation signs.

- Potential health risks associated with mold and decay from moisture retained by termite activity.

Given these threats, implementing pre construction anti termite treatment services in Pune is not just advisable; it is essential for safeguarding investments in property development.

Pre-construction termite treatment is the application of termiticides to the soil and foundation of a building before it is built. This is a proactive measure to prevent termite infestations, which can cause significant structural damage.

Why is it important?

- Termites live in the soil and can easily attack wooden structures.

- Pre-construction treatment creates a chemical barrier that deters termites.

- It’s more effective and less disruptive than post-construction treatments.

Here’s a general process:

- Site Evaluation: A pest control professional will assess the site and create a treatment plan.

- Soil Treatment: Termiticide is applied to the soil before the foundation is poured.

- Foundation Treatment: Termiticide is applied to the foundation walls and footings.

- Slab Treatment: If there’s a concrete slab, the soil beneath it is treated.

- Perimeter Treatment: After construction, the soil around the building’s perimeter may also be treated.

Key things to keep in mind:

- The chemicals used are called termiticides.

- It’s crucial to follow local building codes and regulations.

- The treatment should be done by a licensed pest control expert.

Pre-Construction Anti-Termite Treatments: Frequently Asked Questions

This FAQ is designed to address common questions about pre-construction anti-termite treatments and how they can benefit your new home:

What is Pre Construction Anti Termite Treatment?

Pre construction anti termite treatment involves a series of preventative measures applied to the soil and foundation of a building before the actual construction begins. This treatment is designed to create a protective barrier that deters termites from invading the structure. The process typically includes:

- Soil treatment with specialized chemicals that are effective against termites.

- Application of these chemicals in the foundation trenches, around the perimeter of the building, and in any other areas that may be susceptible to termite entry.

- Regular inspections and maintenance to ensure the effectiveness of the treatment over time.

What are pre-construction anti-termite treatments?

Pre-construction anti-termite treatments involve applying a termite barrier around the foundation of your home before construction begins. This creates a zone of protection against termites trying to enter your structure.

Why choose pre-construction termite treatment?

- Long-lasting protection: Pre-construction treatment offers a long-term barrier against termites, potentially saving you money on repairs and future treatments down the line.

- Easier access: Before construction, pest control professionals have easier access to all areas under the foundation, ensuring a more thorough treatment.

- Cost-effective: Treating during construction can be more affordable compared to retrofitting a finished home.

- Protects your investment: Termite damage can be costly. Pre-construction treatment helps safeguard your new home from these destructive pests.

What are the different types of pre-construction termite treatments?

- Soil treatment: A termiticide is applied to the soil around the foundation, creating a chemical barrier.

- Physical barriers: Products like mesh or stone barriers can be installed to deter termites from entering the structure.

- Treated wood: Using pre-treated lumber for framing can add another layer of protection.

What are the benefits of pre-construction termite treatment compared to post-construction treatment?

- Less disruption: No need to drill holes or trench around your existing foundation after construction is complete.

- More thorough application: Easier access during construction allows for a more comprehensive treatment.

- Potentially lower cost: Treating before construction can be more cost-effective than retrofitting a finished home.

Are pre-construction termite treatments safe?

Modern termite control products are formulated to be safe for people and pets when applied according to the label. A reputable pest control company will use products and methods that prioritize safety.

How long does pre-construction termite treatment last?

The lifespan of a pre-construction termite treatment depends on the product used and soil conditions. However, many treatments can provide protection for several years. Regular inspections by a pest control professional are recommended to ensure continued effectiveness.

Do I still need termite inspections after pre-construction treatment?

Yes, even with a pre-construction treatment, regular termite inspections are crucial. These inspections can identify any potential termite activity and allow for early intervention if needed.

How can I find a qualified pest control company for pre-construction termite treatment?

Look for companies with experience in pre-construction treatments and that are licensed and insured. Ask for references and read online reviews to find a reputable company you trust.